| DW-1300 |

미국 Dupont사의 Tyvek(HDPE 부직포)을 이용하여 제조한 제품으로서 민감한 전자부품 보관 포장하는데 쓰입니다.

Tyvek Bag은 pin-hole성이 우수하고 산소투과에아주 강하며 외부의 충격에도 쉽게 찢어지지 않는 내구성을 가지고 있는

ESD(Elector Static Damage) / EMI (Elector Magnetic Interference) Antistatic Bag입니다. |

| |

|

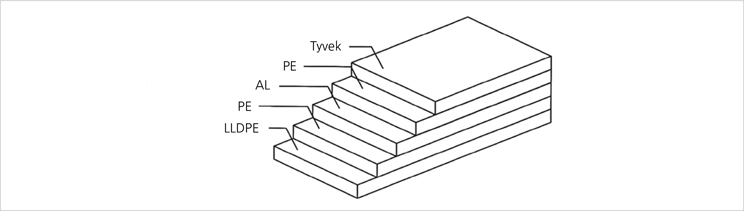

| Material |

1. Tyvek layer

2. Polyethylene layer

3. Aluminium layer

4. Polyethylene layer

3. Linear Low Density Polyethylene layer |

|

| |

규격별로 주문 생산합니다.

(MAX. W:1,250mm가능) |

|

| |

|

| |

| Properties |

Test Methods |

Results |

| Thickness |

ASTM D-374 |

307±60microns |

| Strength |

Breaking Factor |

MD |

ASTM D-882 |

3.80kgf/mm2 |

| TD |

4.35kgf/mm2 |

| Elongation |

MD |

35.5% |

| TD |

34.0% |

| Sealing |

ASTM F88-85 |

3.50kgf/15mm |

| Light Transmission |

ASTM D-1003 |

0.0% |

| Surface Resistivity |

In |

ASTM D-257 |

10e9 ~ 10e12Ωmm |

| Out |

10e9 ~ 10e12Ωmm |

| Static Decay Time |

In |

EIA 541 |

< 0.01 sec. |

| Out |

< 0.01 sec. |

| Tear Strength |

YC-Method |

3.7 kgf |

| OTR |

ASTM D-3985 |

0.0g/m2 24hr latm |

| MVTR |

ASTM F-1249 |

0.0g/m2 24hr |

|

| |